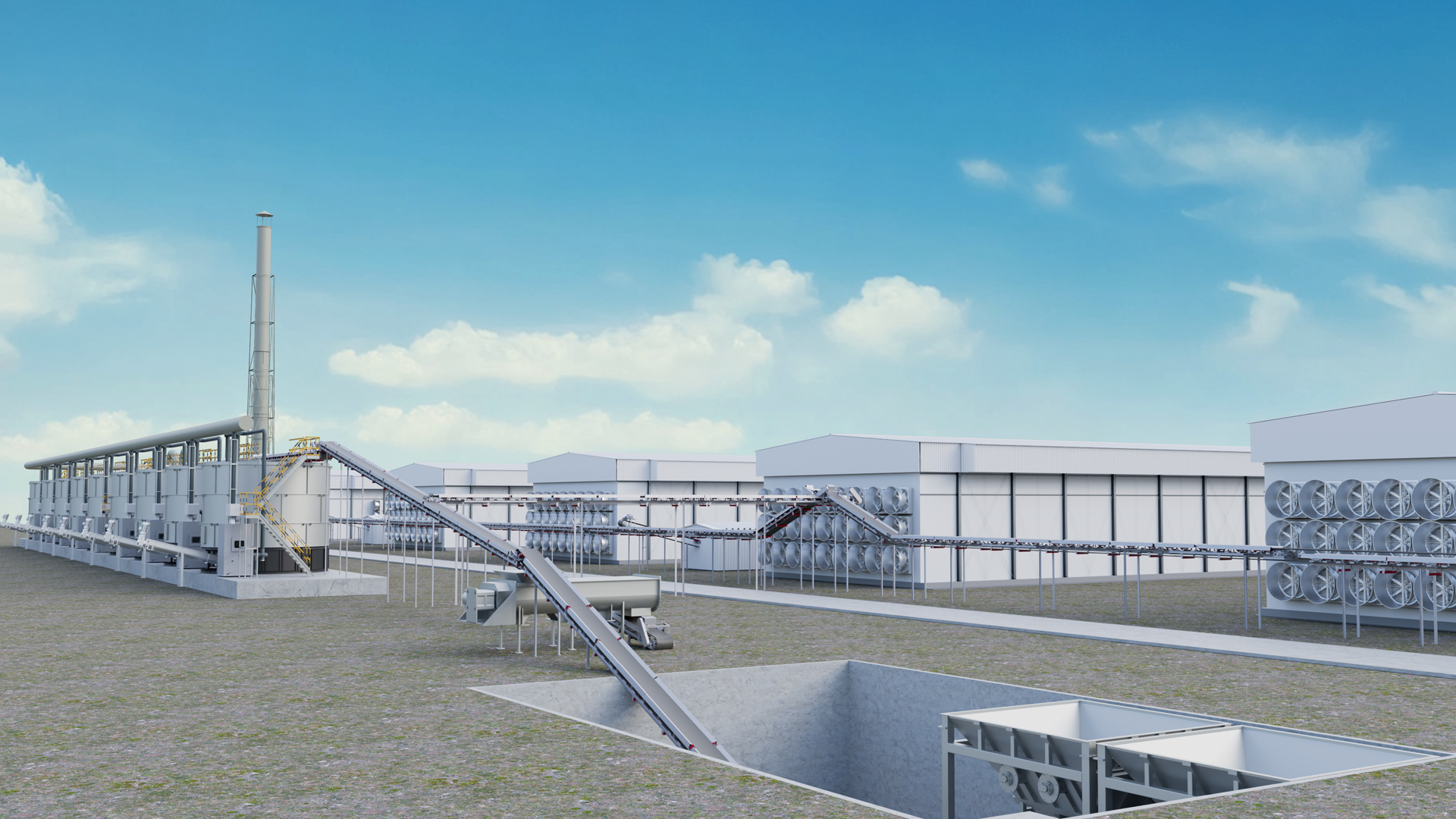

Backed by data from farms across Vietnam, Malaysia, China, and other countries, Cason’s organic fertilizer fermentation tanks deliver up to 40% energy savings while maintaining exceptional fermentation efficiency and stability.

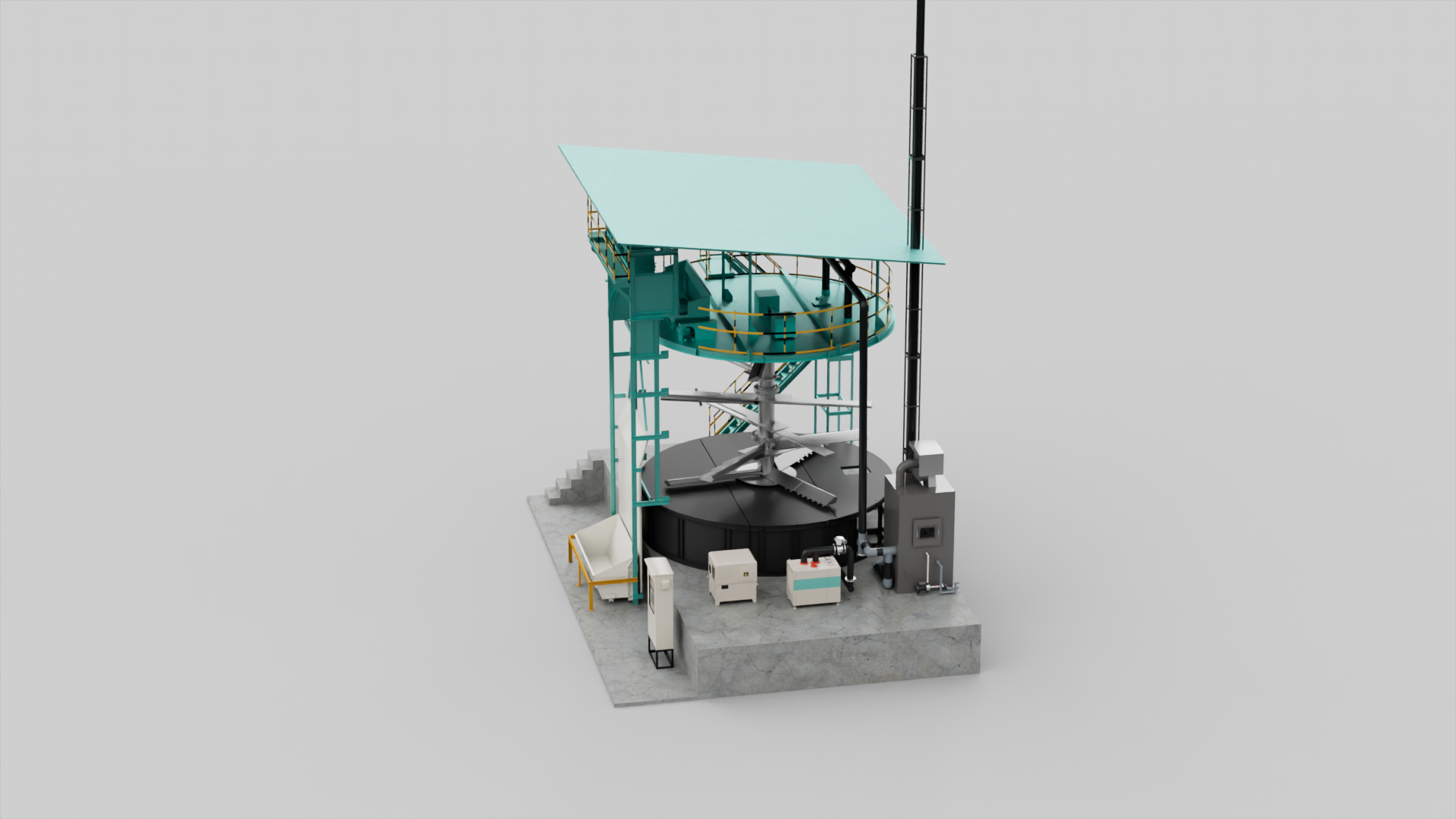

Feeding System: Automatically feeds materials into the tank.

Mixing System: Ensures uniform blending and oxygen distribution.

Hydraulic System: Powers lifting and mechanical movements.

Air Supply System: Provides steady airflow for fermentation.

Fermentation System: Maintains optimal conditions for rapid processing.

Dust Removal System: Filters dust for a cleaner environment.

Deodorization System: Eliminates odors through multi-stage treatment.

Discharge System: Automatically outputs finished compost.

Heating System: Controls temperature for stable fermentation.

To understand how the Cason organic fertilizer fermentation tank achieves efficient and hygienic material handling, it’s important to look at the key components that make up its Remote Conveying System.

From consultation to ongoing support, Cason’s organic fertilizer fermentation tank can be customized according to individual requirements and preferences to create a unique solution.

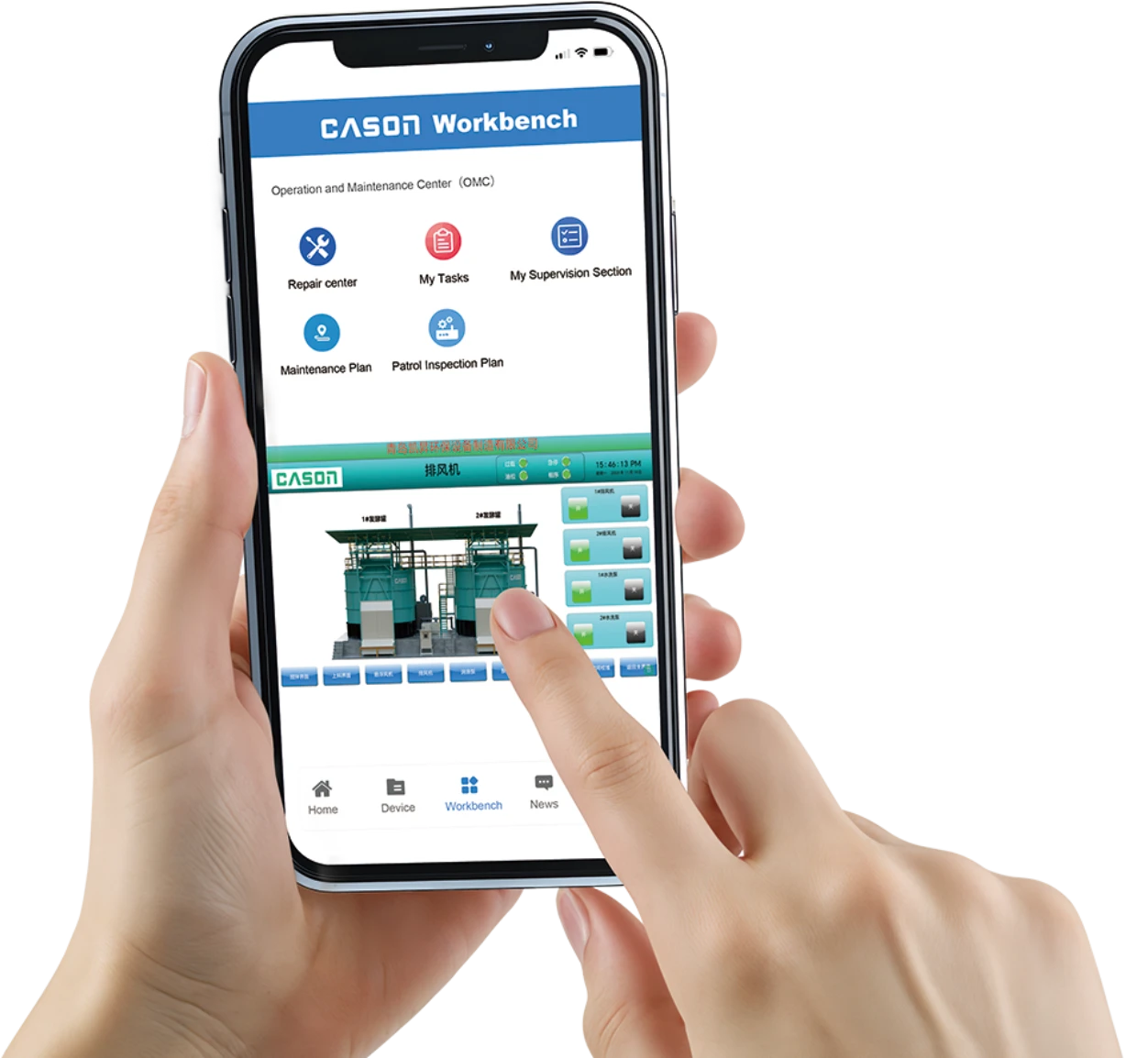

Our organic fertilizer fermentation tank integrates IoT and AI technologies to achieve intelligent, data-driven operation. The AI system analyzes key fermentation data to help adjust and optimize the process. Through IoT connectivity, every equipment is linked to a centralized perform, allowing remote monitoring, fault alerts, and performance analytics. Our clients can make faster decisions and reduce energy consumption for organic waste management.

The main shaft of Cason’s organic fertilizer fermentation tank is made from #25 prime steel, a high-quality carbon structural steel known for its excellent strength and toughness. After forging and normalizing heat treatment, the shaft achieves superior uniformity, durability, and long-term stability during continuous operation. This ensures the fermentation tank for organic waste maintains reliable performance even under high load and temperature conditions.

The organic fertilizer fermentation tank operates on the principle of aerobic microbial fermentation. Microorganisms rapidly break down the organic matter and residual protein in animal manure and kitchen waste under controlled temperature and sufficient oxygen. r. The bucket elevator lifts raw materials and deposits them automatically into the tank, where stirring blades mix the waste thoroughly. A special heat exchanger recycles the exhaust heat to warm fresh air, which is then blown through the blades, accelerating both aerobic fermentation and moisture evaporation. After an average of 7 days, the tank converts the organic waste into high-quality organic fertilizer, ready for collection and further use.

One of the key features of Cason’s organic fertilizer fermentation tanks is odor control. The tank is designed with a sealed structure that prevents the release of foul-smelling gases into the environment. Additionally, the aeration system ensures the fermentation process is aerobic, reducing the likelihood of producing odors like ammonia.

A Cason fermentation tank is designed to keep moisture levels between 50%-60% for optimal fermentation. This is monitored automatically by the tank’s built-in sensors, which adjust water spray or drainage as needed. Too much moisture can lead to sludge buildup, while too little moisture can slow the fermentation process and hinder microbial activity.

Yes, Cason offers an 8-year premium care program. Beyond warranty, we continue to provide on-site maintenance at a cost price, ensuring worry-free, long-term operation of your animal manure fermentation tanks.