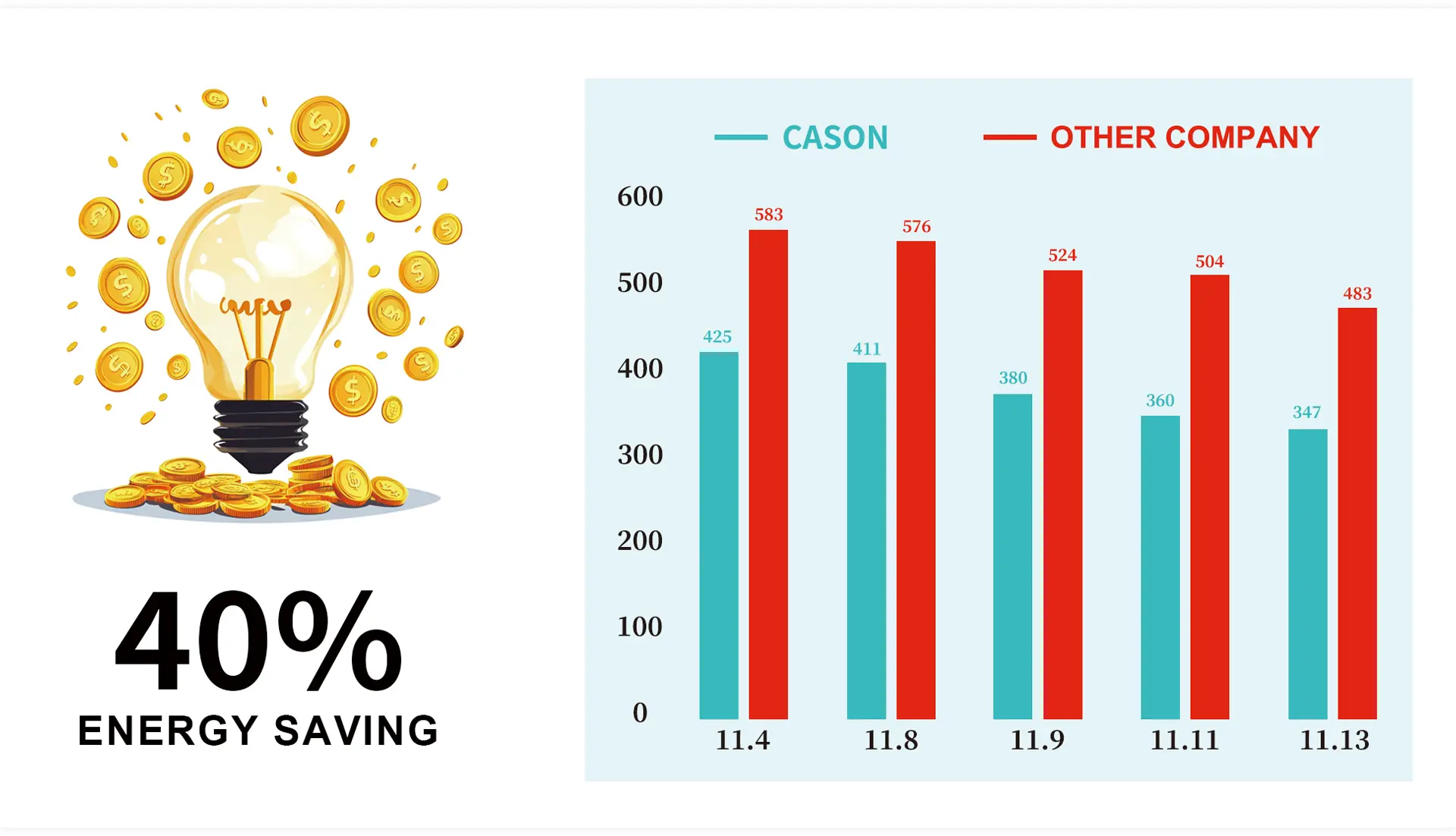

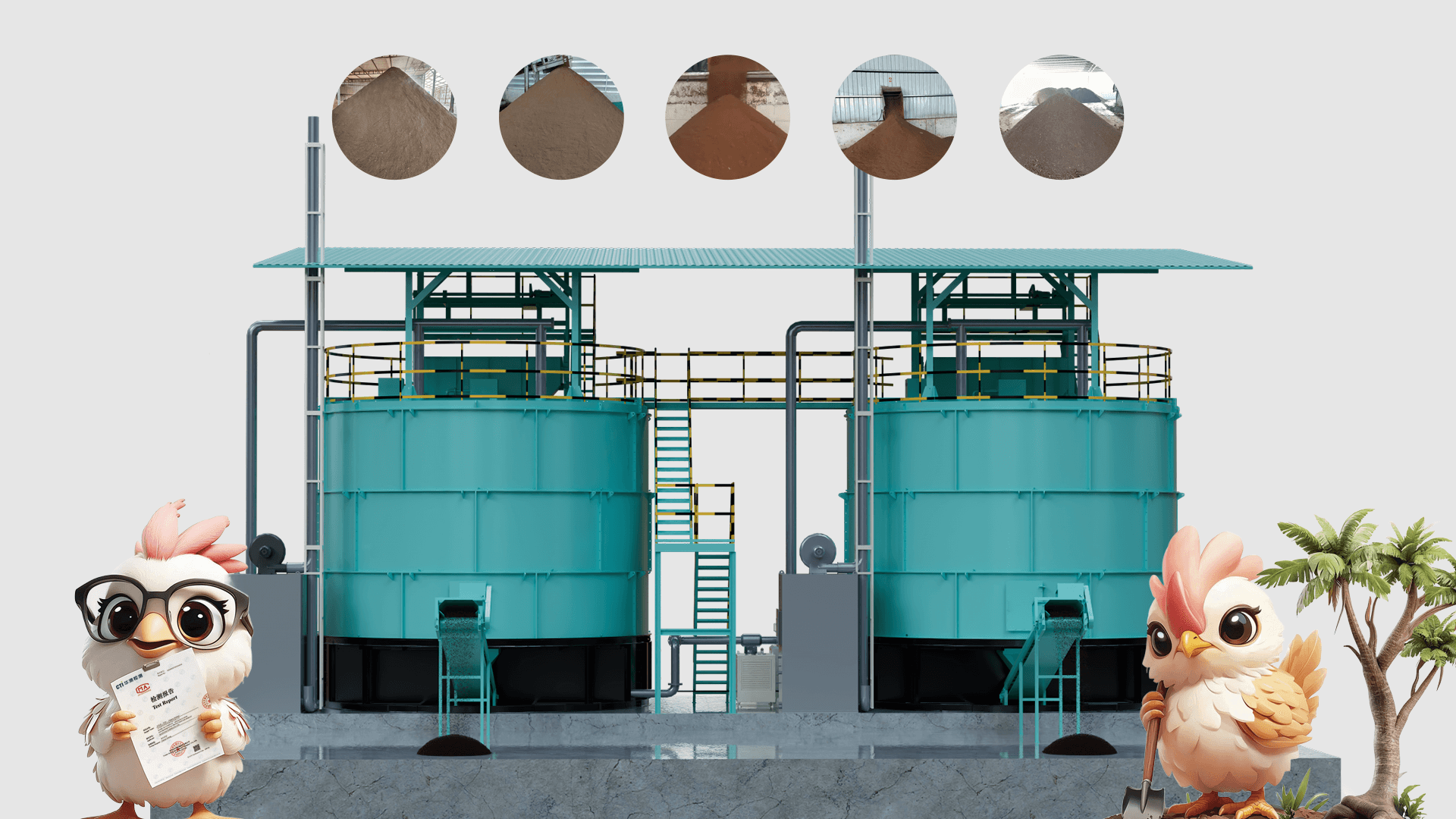

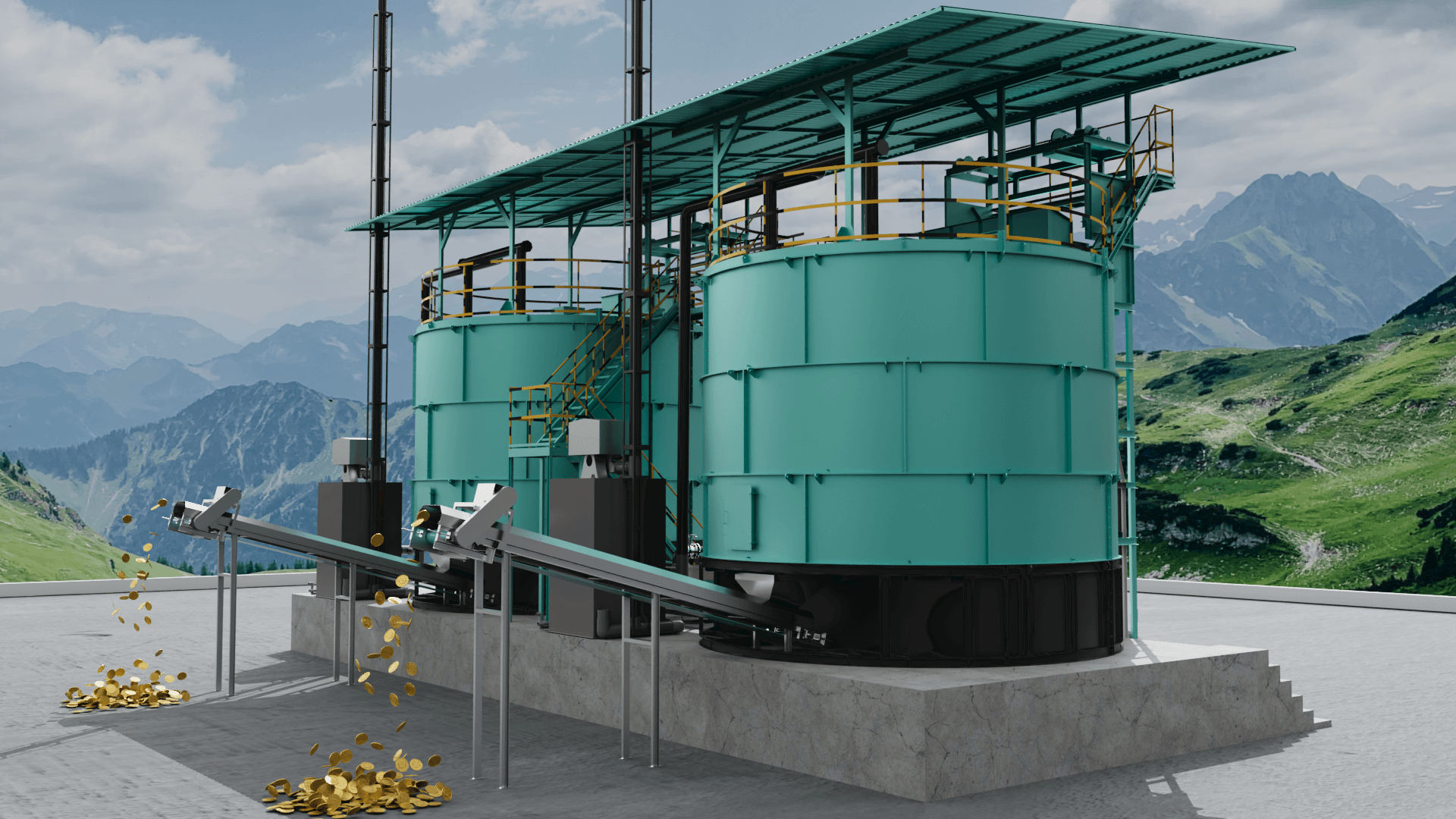

Animal manure fermentation equipment empowers sustainable production through intelligent design and superior energy-saving performance

Not just a claim, but backed by real data and technology.

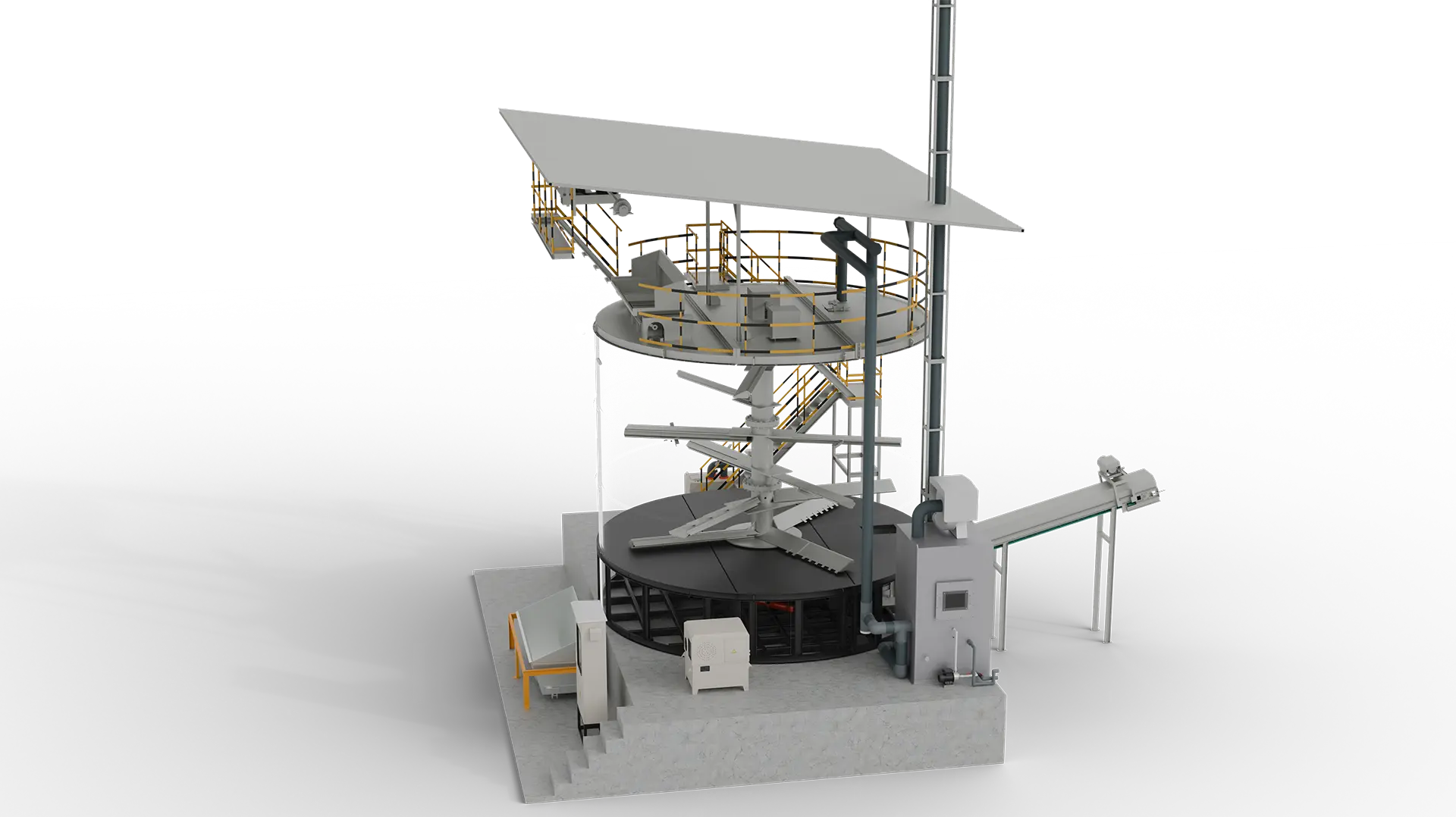

The remote conveying system automatically transfers raw materials and fermented products between process stages, greatly reducing manual handling and operational costs. Its modular and flexible layout allows adaptation to various plant designs, improving space utilization while maintaining a clean, enclosed, and continuous production flow.

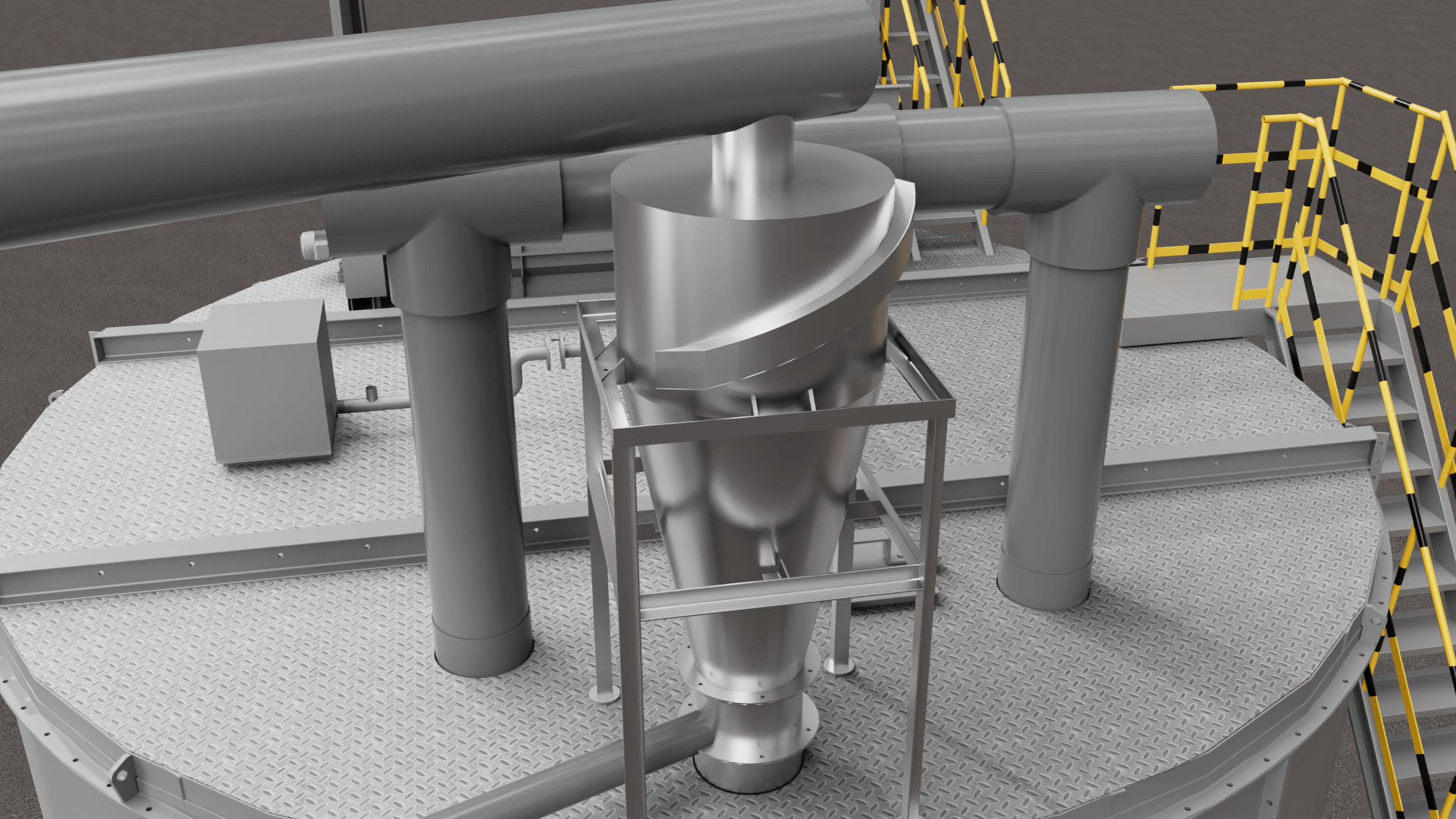

As an essential extension of the conveying system, the hopper lifting system is designed to vertically transfer materials from the ground level to the animal manure fermentation tank inlet. Working in coordination with Cason’s intelligent conveying system, it enables smooth, automatic, and precise feeding.

In Cason’s animal manure fermentation equipment, the hopper lifting system adopts a bucket elevator design to deliver animal manure efficiently into the fermentation reactor. After manure is fed into the elevator path, the buckets continuously scoop and lift the material, powered by an electric motor, and discharge it precisely into the top of the fermentation tank. This fully enclosed and automated system operates in coordination with Cason’s conveying system, maintaining a steady, hygienic, and continuous feeding process throughout the fermentation cycle. The system supports large-scale operations while helping farms maintain eco-friendly and sustainable practices.

Cason animal manure fermentation tank is designed with a centralized odor control system to manage harmful gases from multiple fermentation tanks. The odors are collected and treated through advanced deodorization processes, ensuring that the processed gases are colorless, odorless, and environmentally safe before being released at high altitude. With the odor control system, the organic manure fermentation tanks have become more eco-friendly.

Water Scrubbing: Removes large dust particles and partially soluble gases.

Acid Washing: Neutralizes alkaline odor components, such as ammonia.

Alkali Washing: Removes acidic odor components, such as hydrogen sulfide.

Biological Deodorization: Decomposes remaining organic gases using microorganisms.

Generally, our animal manure fermentation tanks are the most durable type in the industry; this is also the feature of the label impression for most of our customers at home or abroad. Skilled workers and a strict quality control system can ensure every machine with best working performance.

Farm scale(livestock on hand), way of disposing animal waste (conveyor belt or scraper), water content, handling capacity, motor, material name, pump, etc.

Each manure fertilizer fermentation tank from Cason is fully sealed and equipped with a centralized deodorization system. It eliminates odor leakage, sterilizes pathogens, and prevents wastewater seepage, helping farms meet strict environmental standards.

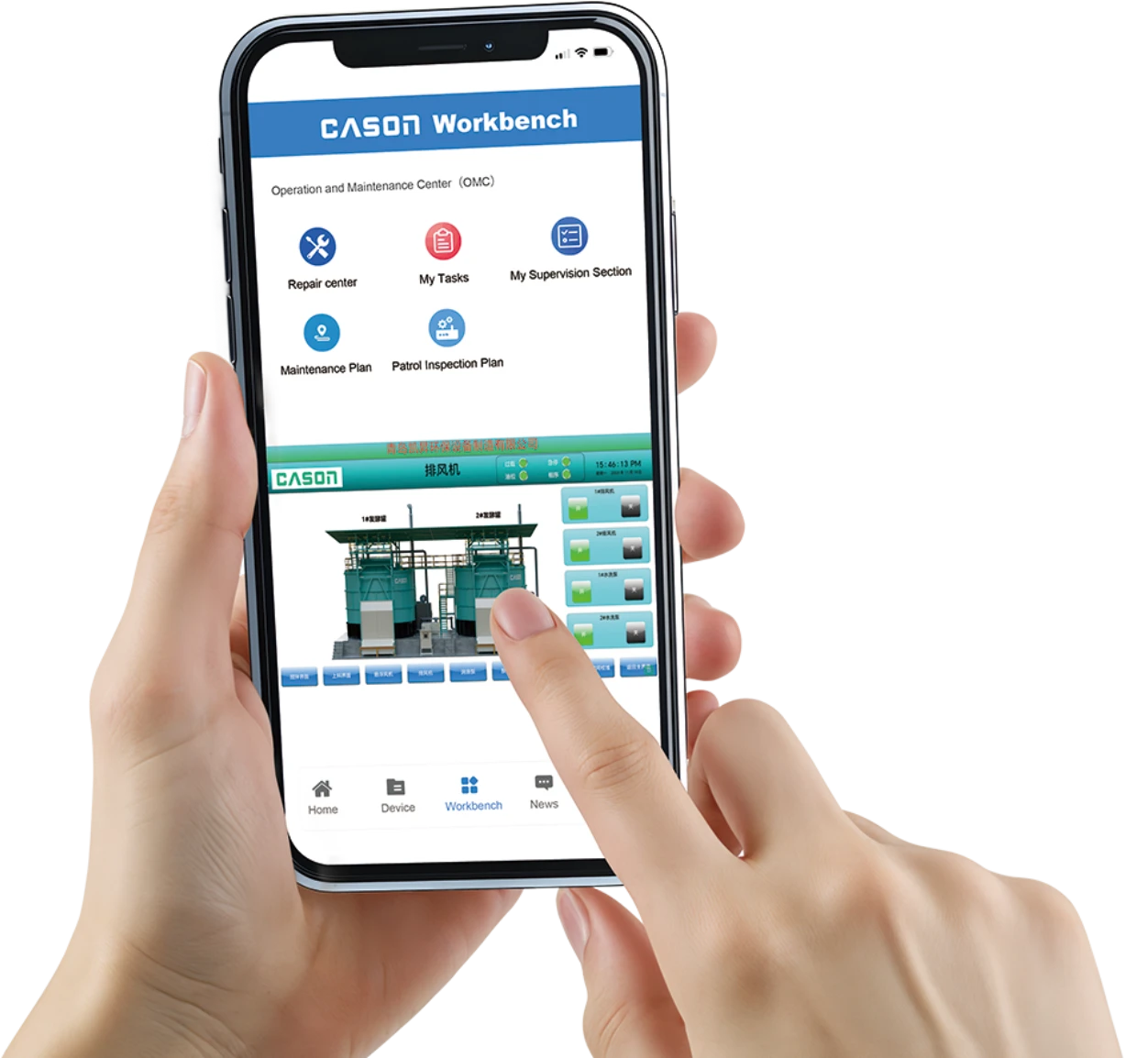

Cason’s fermentation tank features intelligent control systems with real-time monitoring of temperature, oxygen, and fermentation conditions. Modular design allows expansion, and mobile tracking ensures convenient operation from anywhere on the farm.

Cason animal manure fermentation tanks come with expert installation, free consumables, and a maintenance toolkit. Our global service network provides rapid response, on-site support, quarterly inspections, and an 8-year premium care program, ensuring long-term, worry-free operation.